Schaeffler provide critical bearing for the Panama Canal expansion

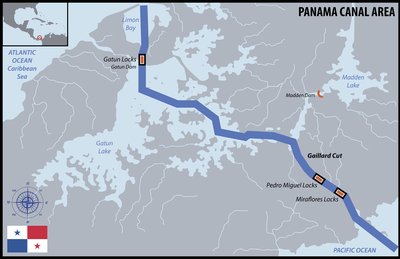

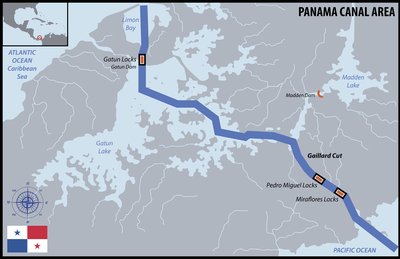

Shanghai June 30, 2016 / PRNewswire / - lasted nine years, the Panama Canal expansion project on June 26 officially completed, the newly built locks and waterways, there are 3,400 bearings from Schaeffler at work, make greater tonnages available to and from the Atlantic and Pacific.

To ship to overcome a height difference of 26 meters and passed in this country in the hinterland, the Atlantic side and the Pacific Ocean side of the lock must be installed. Schaeffler components manufacturing plays a crucial role in the process of running the ship lock. (Picture: Schaeffler)

To ship to overcome a height difference of 26 meters and passed in this country in the hinterland, the Atlantic side and the Pacific Ocean side of the lock must be installed. Schaeffler components manufacturing plays a crucial role in the process of running the ship lock. (Picture: Schaeffler)

Although the Panama Canal expansion project at the high technical requirements, but the foundation is still Schaeffler standard products successfully developed a number of solutions. Weighing up to 3,100 tons of lead wheel locks are equipped with self-aligning rolling bearing manufacturer Schaeffler. (Picture: Schaeffler)

Critical bearing solutions provided by the Schaeffler make the Panama Canal locks and valves to reliable operation. In the future, 366 meters long, 50 meters wide, smooth navigation of ships in this shortcut between the two oceans. Previously, the channel length is limited not more than 290 meters, a width of not more than 32 meters of the ship navigation.

Promote maximum torque of 330,000 Nm

To overcome the two oceans ship 26 meters height difference and passed through the hinterland of the country, the Atlantic side and the Pacific side of the lock must be installed. To this end, the project installed submerged three successive lock in the adjacent reservoir water source. The lock made of reinforced concrete, a large body: 50 meters wide, 30 meters high, 10 meters thick. For security reasons, access to the major sides of the dam are fitted with two locks. Lock switch device developed by the Italian engineering company Cimolai Technology. Each lock comes with two main drive unit for driving the cable winch, the locks were opened or closed. Cable winch drum manufactured by the Schaeffler-aligning roller bearings. Because of the need to move lock up 330 000 Nm of torque, and therefore each cable winch is also equipped with a gearbox, the motor torque increased nearly 280-fold. Transmission by the Brevini PIV Drives Group's research and development, and exclusively equipped Schaeffler developed tapered roller bearings, spherical roller bearings and cylindrical roller bearings. Most bearings are coated with a coating Schaeffler Triondur C, which can effectively prevent wear and ensure bearing life of 35 years.

To ship to overcome a height difference of 26 meters and passed in this country in the hinterland, the Atlantic side and the Pacific Ocean side of the lock must be installed. Schaeffler components manufacturing plays a crucial role in the process of running the ship lock. (Picture: Schaeffler)

To ship to overcome a height difference of 26 meters and passed in this country in the hinterland, the Atlantic side and the Pacific Ocean side of the lock must be installed. Schaeffler components manufacturing plays a crucial role in the process of running the ship lock. (Picture: Schaeffler)

Although the Panama Canal expansion project at the high technical requirements, but the foundation is still Schaeffler standard products successfully developed a number of solutions. Weighing up to 3,100 tons of lead wheel locks are equipped with self-aligning rolling bearing manufacturer Schaeffler. (Picture: Schaeffler)

Critical bearing solutions provided by the Schaeffler make the Panama Canal locks and valves to reliable operation. In the future, 366 meters long, 50 meters wide, smooth navigation of ships in this shortcut between the two oceans. Previously, the channel length is limited not more than 290 meters, a width of not more than 32 meters of the ship navigation.

Promote maximum torque of 330,000 Nm

To overcome the two oceans ship 26 meters height difference and passed through the hinterland of the country, the Atlantic side and the Pacific side of the lock must be installed. To this end, the project installed submerged three successive lock in the adjacent reservoir water source. The lock made of reinforced concrete, a large body: 50 meters wide, 30 meters high, 10 meters thick. For security reasons, access to the major sides of the dam are fitted with two locks. Lock switch device developed by the Italian engineering company Cimolai Technology. Each lock comes with two main drive unit for driving the cable winch, the locks were opened or closed. Cable winch drum manufactured by the Schaeffler-aligning roller bearings. Because of the need to move lock up 330 000 Nm of torque, and therefore each cable winch is also equipped with a gearbox, the motor torque increased nearly 280-fold. Transmission by the Brevini PIV Drives Group's research and development, and exclusively equipped Schaeffler developed tapered roller bearings, spherical roller bearings and cylindrical roller bearings. Most bearings are coated with a coating Schaeffler Triondur C, which can effectively prevent wear and ensure bearing life of 35 years.